Furniture Manufacturing Facility-1

The client’s business program is to manufacture contemporary and ergonomic range of furniture for commercial and residential spaces which are required for his large scale turn-key project contracts.

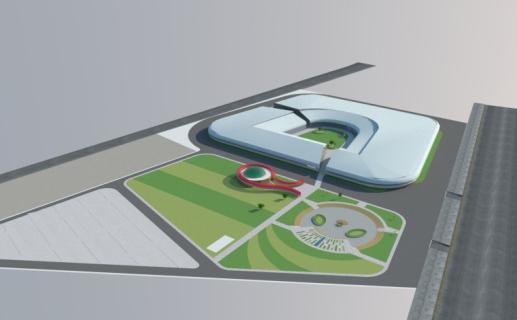

The project, located in Mumbai city, came as an opportunity to show the metamorphosis of a utilitarian factory building, from its dilapidated state into a modern, efficient and sustainable design.

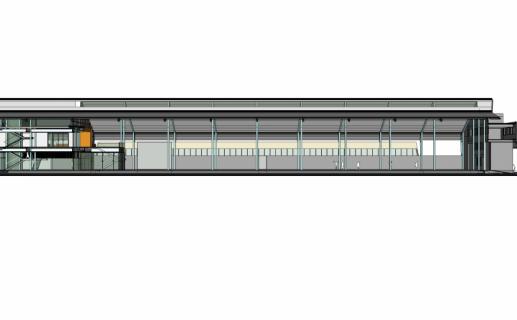

Our entire focus was on improvising the quality of interior work spaces with an integrated segregation of creative, administrative and production work environments within a single shell. The over-all form is an outcome of the spatial arrangements and enhancement of daylight quality.

The East-West alignment of the building allows withdrawing a continuous linear passage of North light through the roof. The light enables higher efficiency in working throughout the spaces. This has also defined the building’s profile which can be read from the main road thus creating an iconic facade of the factory in the Industrial skyline.

The whole structure is a Pre-Engineered Building, with glass and terracotta materials used in the facades to add visual connection and break the monotony of profile sheets respectively, making it visually lighter yet bold.

The most challenging part of the project was its tight schedule! Before finalizing on the Architectural design, the machineries were already ordered by the client. These machineries being imported and they were arriving in the month of July which is the peak of heavy rainfalls in Mumbai. We generally provide Process planning for manufacturing unit including machinery layout for our Industrial projects which involves a thorough understanding of the manufacturing process and coordination with machine manufacturers and various vendors/contractors. Particularly for this project we had very less time for Design Development and Process Planning. We managed to design, manufacture and execute the roofing for the building on priority in four months so that the machineries are well protected on their arrival which was an achievement in itself. This was possible only because of Pre-Engineered Steel Structure, simplicity in design and functional phase-wise execution. The wall sheeting work followed soon after. The whole structure was completed in 9 months of duration.

The steel members within the interior spaces reflect modernity with enhanced volumes that further provides better scope for interior segregation of functions.

Related Industrial & Infrastructure Projects